Emikhakheni eminingi efana nokukhiqizwa kwezimboni, ukuvikelwa kwebhilidi, uthango lwezolimo kanye nokuhlobisa ikhaya, i-welded mesh isibe enye yezinto ezidingekayo ngamandla ayo esakhiwo kanye nokusebenza okubanzi. Ukhiye wokuzinza nokuqina kwe-mesh eshiselwe ezindaweni ezihlukahlukene ukuklanywa kwesakhiwo esiyingqayizivele nesinhle kakhulu. Lesi sihloko sizohlaziya ngokujulile amandla esakhiwo semeshi eshiselwe futhi siveze imfihlo yokuqina kwayo.

1. Inqubo yokukhiqiza kanye nesakhiwo esiyisisekelo seanezikhala ezishiselwe

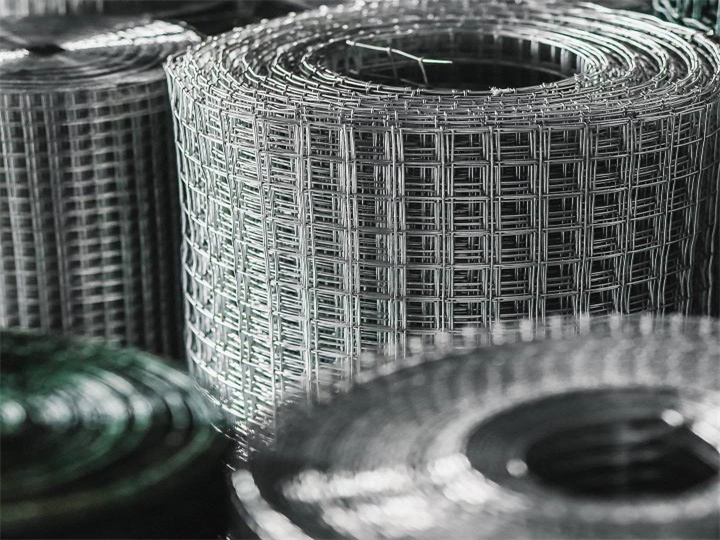

Njengoba igama libonisa, i-welded mesh iyisakhiwo se-mesh esakhiwe izintambo zensimbi eziphambanayo ndawonye ngokusebenzisa i-welding kagesi. Kule nqubo, izintambo zensimbi ziyancibilika emazingeni okushisa aphezulu futhi zixhumeke ngokuqinile ukuze zakhe ama-node aqinile. Lawa ma-node awagcini nje ngokuthuthukisa ukuzinza kwe-mesh, kodwa futhi aqinisekisa umthamo wokuthwala we-mesh eshiselwe lapho ubhekene nomthelela wamandla angaphandle.

Isakhiwo esiyisisekelo se-welded mesh ngokuvamile sihlanganisa usayizi we-mesh, ububanzi bocingo lwensimbi kanye nokuhlelwa kwamaphoyinti okushisela. Usayizi we-mesh unquma ukungena kwe-mesh eshiselwe, kuyilapho ububanzi bocingo lwensimbi buthinta ngqo amandla ayo okuthwala umthwalo. Ukuhlelwa kwamaphoyinti okushisela kuhlobene namandla kanye nokuqina kwe-mesh eshiselwe. Isakhiwo se-welding esinengqondo singahlakaza amandla angaphandle futhi sigweme umonakalo odalwe ukugxila kwengcindezi yendawo.

2. Izakhi ezibalulekile zamandla esakhiwo

Izinto kanye nobubanzi bocingo lwensimbi:Izinto ezivamile zensimbi zemeshi eshiselwe zihlanganisa intambo yensimbi enekhabhoni ephansi, intambo yensimbi engagqwali kanye nentambo yensimbi. Izintambo zensimbi zezinto ezihlukahlukene zinamandla ahlukene nokumelana nokugqwala. Ubukhulu be-diameter yocingo lwensimbi, amandla okuthwala umthwalo we-welded mesh, kodwa ukungena kuzoncishiswa ngokufanele. Ngakho-ke, lapho ukhetha i-mesh eshiselwe, kuyadingeka ukulinganisa lezi zici ezimbili ngokuya ngesimo esithile sohlelo lokusebenza.

Inqubo yokushisela namandla e-node:Inqubo yokushisela ye-weld mesh ibalulekile emandleni esakhiwo sayo. I-welding yekhwalithi ephezulu ingaqinisekisa ukuxhumana okuqinile phakathi kwezintambo zensimbi futhi kwakha ama-node azinzile. Lawa ma-node angadlulisela ngempumelelo futhi ahlakaze ingcindezi lapho engaphansi kwamandla angaphandle ukugwema ukuguquguquka noma ukuphuka kwemeshi. Ngaphezu kwalokho, inombolo kanye nokuhlelwa kwamaphoyinti wokushisela kuzophinde kuthinte amandla aphelele we-mesh ehlanganisiwe. Isakhiwo se-welding esinengqondo singathuthukisa ukuzinza nokuqina kwe-mesh eshiselwe.

Idizayini yegridi nokuvumelana nezimo kohlelo lokusebenza:Idizayini yegridi ye-mesh eshiselwe ayithinti nje kuphela ubuhle bayo, kodwa futhi ihlobene eduze namandla esakhiwo. Amameshi amancane anganikeza ukuvikeleka okungcono, kodwa angadela izinga elithile lokungena. Ngakho-ke, lapho uklama i-mesh eshiselwe, kuyadingeka ukukhetha usayizi we-mesh ofanele ngokuya ngezidingo zesimo sohlelo lokusebenza. Ngesikhathi esifanayo, umklamo we-mesh we-mesh eshiselwe kufanele futhi ucabangele ukunethezeka kokufakwa nokugcinwa kwawo ukuze kuqinisekiswe ukuzinza nokuthembeka kwawo ekusetshenzisweni kwesikhathi eside.

3. Ukusetshenziswa okungokoqobo kwamandla esakhiwo semeshi eshiselwe

Amandla esakhiwo se-welded mesh asetshenziswe kabanzi emikhakheni eminingi. Emkhakheni wokwakha, i-welded mesh isetshenziswa njengokuqinisa udonga, ukusekela phansi kanye nocingo oluvikelayo, futhi isakhiwo sayo esiqinile singakwazi ukumelana nemithwalo emikhulu namandla omthelela. Emkhakheni wezolimo, i-welded mesh, njengento yokubiya, ingavimbela ngempumelelo ukuphunyuka kwezilwane nokuhlasela kwamanye amazwe, futhi ivikele ukuphepha kwezitshalo nemfuyo. Ngaphezu kwalokho, i-welded mesh nayo idlala indima engenakushintshwa kwezokuthutha, izimayini, ukuhlobisa ikhaya neminye imikhakha.

Isikhathi sokuthumela: Jan-24-2025